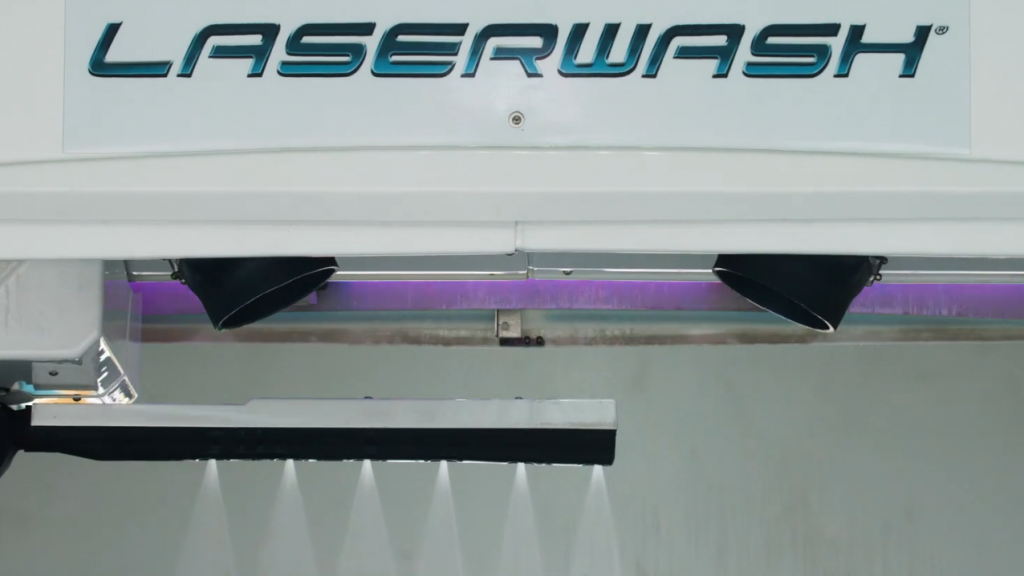

Carwash World is the proud, exclusive distributor of the PDQ LaserWash™ 360 Plus in New South Wales, Australian Capital Territory, South Australia, the Northern Territory and Queensland.

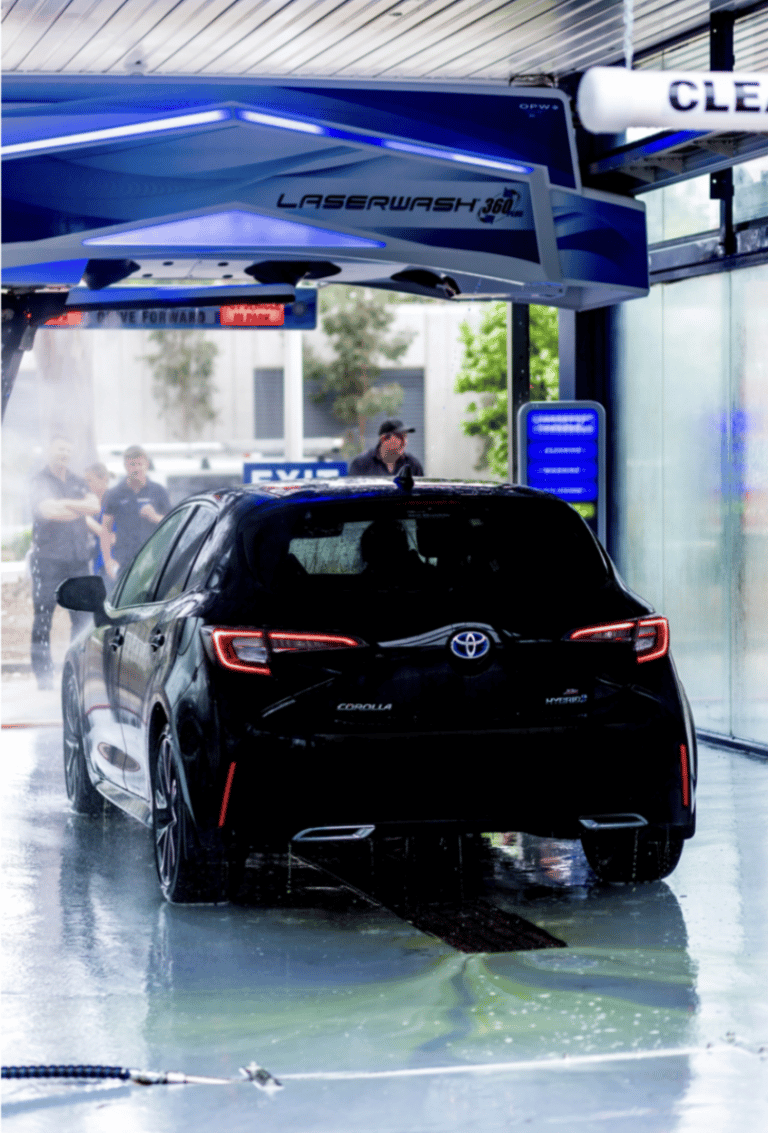

The LaserWash™ 360 Plus is the world’s leading touchless car wash, delivering reliability and the industry’s best return on investment.

Get more cars washed per hour thanks to substantially faster wash speeds compared to other in-bay automatics. Your customers will absolutely love the shorter lines!

Enhance your revenue with upsells from a series of awe-inspiring features that customers will love, including high side blasters, in-bay lighting, and over-glow.

Efficient design, lower water usage and Smart™ 360 Technology, that ‘thinks for itself’ all increase up-time, optimise the wash process and reduce operating costs for you.

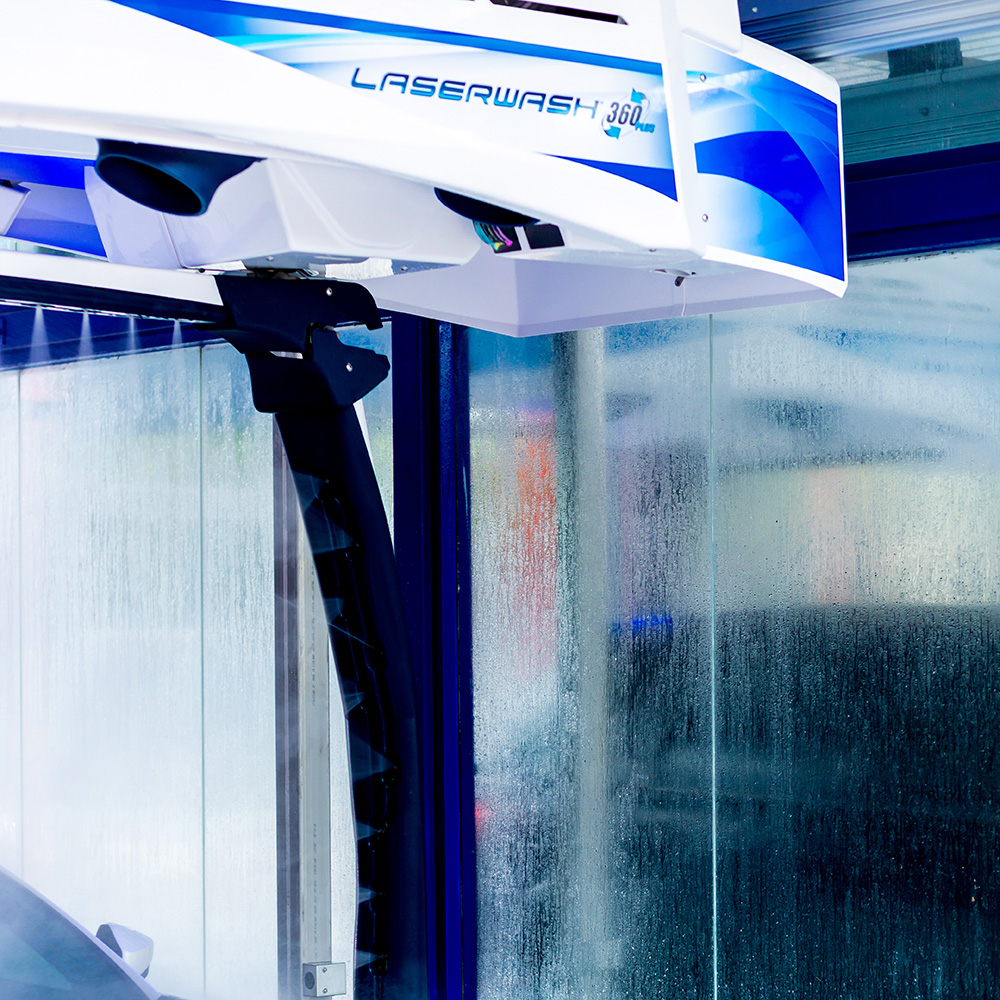

The LaserWash 360 Plus has less moving parts. It has an innovative design. It is made from industry-leading non-corrosive stainless steel and aluminium parts, with excellent resistance to water and chemicals.

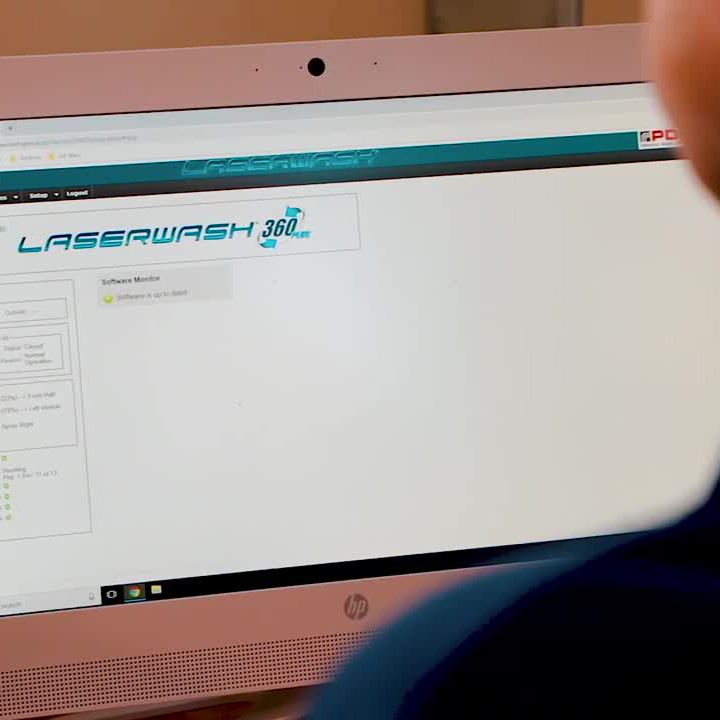

It has cloud access to sales reports and breakdowns, which allows you to stay in touch with your business as it’s running, from wherever you are.

It runs fast, cleaning more cars per hour than other in-bay automatics, and with more add-ons available for extra revenue.

Improved throughput. Increased revenue. Reduced costs.

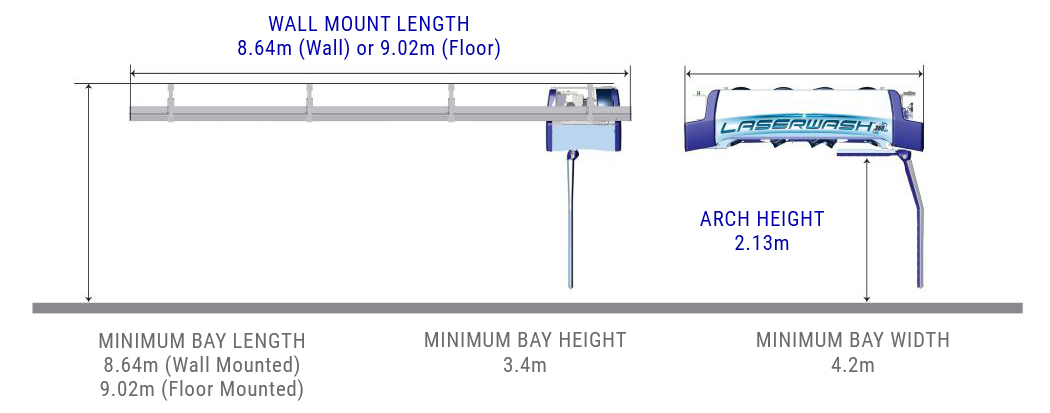

The LaserWash™ 360 Plus can fit into a variety of wash bay configurations - wall-mounted or free-standing - with adjustable support rails to accommodate various lengths.

The Virtual Treadle locates the vehicle, eliminating the need for drive-on floor-mounted mechanisms and leaving customers with a comfortable, inviting bay.

The modern Arch Control System uses advanced automatic obstacle guidance to locate trailer hitches, side mirrors and other vehicle extrusions, making it a safer wash for your customers and the wash of choice for car enthusiasts.

The LaserWash™ 360 Plus is fitted with Smart 360 Technology throughout, allowing the machine to ‘think for itself’. You’ll spend less time on problems and more time on the things that matter to your business.

The Virtual Treadle is an innovative electronic system that senses the positioning of the car within the bay. Ultrasonic sensors measure the vehicle’s width while bridge sensors signal the driver to move forward or back. The system accommodates for off-centre and angled vehicles.

The Arch Control System then takes over, keeping a safe distance from the vehicle during the wash and making no contact, avoiding protrusions and remembering obstacles. The arch focusses on addressing the body style changes of today’s modern vehicles, working from both the top and side manifolds to thoroughly clean hard to reach spots, such as underneath spoilers on rear windows.

The redesigned HP Pump Station offers added durability along with an increase in ease of serviceability. The all-stainless steel frame houses a dedicated fluid manifold designed to reduce fitting connections and reduce leak points. The chemical injection manifold has also been positioned for easy service access as well as increased durability.

The LaserWash™ 360 Plus advanced cover package is both attractive and functional. This standard inclusion offers a complete state-of-the-art look that is sure to impress your customers. Underneath the covers, a separate enclosure for air valves has been added to the bridge, while all fluid valves have been removed, increasing overall reliability and serviceability.

The advanced browser-based wash control system provides access to all key operating functions. You can program wash packages and machine functions, monitor sales activity, obtain real-time wash data and eliminate unnecessary wash site visits. Get alerts sent to your phone informing you of critical issues that may be occurring at your wash locations. This easy-to program capability keeps you in touch with all of your sites from anywhere, at any time.

When you choose to install a LaserWash™ 360 Plus, you’ll be opening yourself up to a huge number of add-ons that will generate extra revenue, ensure a more thorough clean and wow your customers.

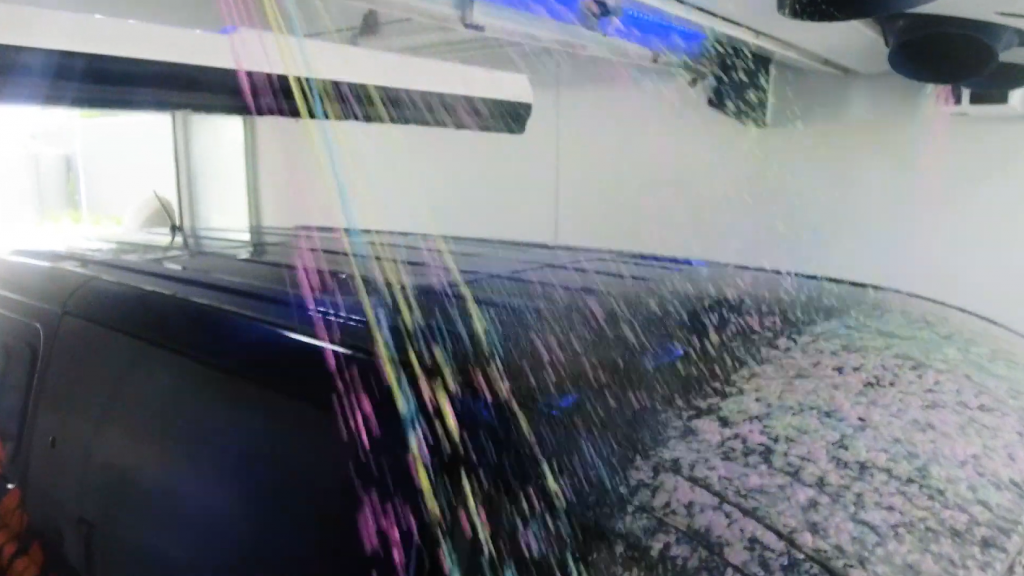

The LaserGlow Illumination System is one of these premium additions, putting on a sensational light show during the wash and providing even greater assistance during the loading process.

Likewise, the OverGlow Hi-Gloss Applicator will coat your customer’s vehicle in a thick sheet of cleaning solution while strategically placed bright LED lights create an exciting experience for occupants of the vehicle.

Make your car wash the most memorable one in town with these and more optional premium add-ons.

Your enquiry has landed safely in our inbox, and we greatly appreciate your interest. Our team is on the case and will be in touch with you soon to provide the information or assistance you need.

We look forward to connecting with you shortly!

Best regards,

Carwash World Team